Process

Huawei Investment Casting backed up by our modernized workshops, reliable equipment and advanced manufacturing technology, we are devoting to manufacturing high quality industrial products for our customers. We have abundance of experience in

Lost Wax Casting, Lost Foam Casting, Shell Mold Casting,Sand Casting, Silica Sol casting,forging, precision machining, surface treatment, sheet metal, welding, and assembling which we would like to share with you and be of your service.

Manufacturing Process--Lost Wax Casting(Precision Casting)

Manufacturing Process--Lost Wax Casting(Precision Casting)

|

|

|

|

|

|

|

|

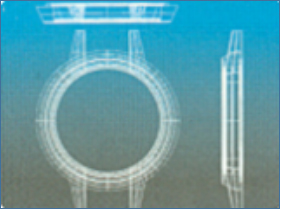

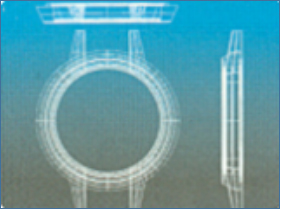

Process Design |

|

Tooling Making |

|

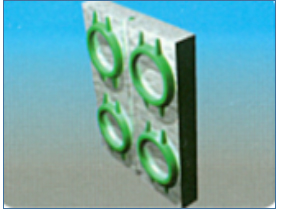

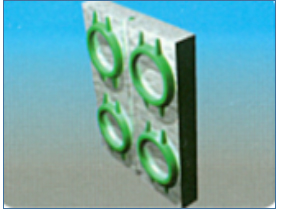

Wax Injection |

|

Wax Patten Assembly |

|

|

|

|

|

|

|

|

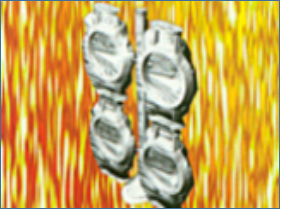

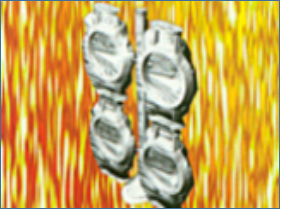

Mold Preheat |

|

Wax Removal |

|

Stuccoing |

|

Dipping |

Manufacturing Process--Lost Wax Casting(Precision Casting)

|

|

|

|

|

|

|

|

Casting |

|

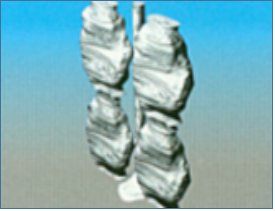

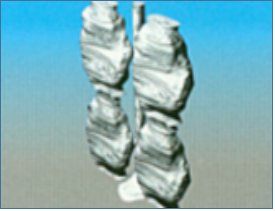

Mold Shake Out |

|

Work Piece Cut-off |

|

Grinding |

|

|

|

|

|

|

|

|

Pack&Transport |

|

Final inspection |

|

Machining |

|

Heat Treatment |

|

|

|

|

|

|

Design |

Mold Processing |

Mold Pre-heat |

Optical Spectro-meter |

Lost Wax Casting(Precision Casting)Technology Specification:

Casting Process: Water glass process of lost wax investment casting

Material Range: Carbon steel .low alloy steel

Material Standard: GB.ASTM. AISI. DIN. BS. JIS. NF. AS, AAR

Max linear Size:1200mm:Max Diameter Size:600 mm

Casting Weight range: 0.1-90Kg

Casting Dimension Tolerance: CT7

Casting Surface Roughness: Re 12.5um

Lost Wax Casting Applicable fields for our product:

Train&railway, automobile&truck, construction machinery, mining machinery, forklift, agricultural machinery,

shipbuilding, petroleum machinery, construction, valve and pumps, electric machine,hardware, power equipment and so on.

Huawei Investment Casting is able to offer its own

Project management

Solutions

Casting

Heat treatment. Machining. Surface treatment.

Assembly

Customer services

Characteristics of casting

The main advantages of Lost Wax Casting(Precision Casting)are:

Choice of material.

Freedom in design.

Close tolerances

Fine surface finish.

Reduce costs